Given motodesign born early 2015 and has as its primary objective the design of motorcycles for private clients who want a made to measure, but also the design for companies that want to bring their idea into production.

Given motodesign born early 2015 and has as its primary objective the design of motorcycles for private clients who want a made to measure, but also the design for companies that want to bring their idea into production.

For companies it, it is important to search for new forms, new features, new ideas. Develop these skills internally, however, it can be expensive and time-consuming. It is also good that the creative ideas come from outside, this can become a reason research and development for internal projects.

We treat the stage or Advanced Concept concept trying to interpret the stylistic requirements of the customer, current and especially future trends, the actual technique and near future. We try to do all this with a mind free from preconceptions, creating objects that have feet on the ground only to the extent required by the customer, in the absence of explicit requests we orient ourselves towards an Advanced concept that can be much more challenging for us and for the end user.

What distinguishes us from other motorcycle enthusiasts, It is that we like to get our hands dirty with grease and oil, worship chip, but we are also planning fanatics computer. So our first approach to designing is computerized and especially 3D mode. With our software and hardware and with our hands we create surfaces in class A or B, Solid or simply by rendering models that are both beautiful but also and above all functional. Functional means that you can send them directly to a mill, a 5 axes or a rendering machine, and you will not have weight problems, undercuts, or other.

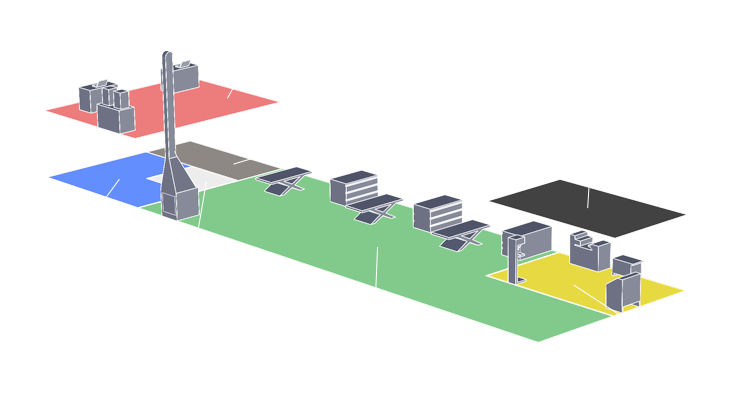

Structure

Given is a young motorcycle design and planning workshop, formally founded recently but making use of our long experience in the development of the bikes, and thanks to previous experiences in Aprilia, and struggling, then in CR&S ed ultimamente in Matchless. Given also lives thanks to the enthusiasm and professionalism of its employees.

He lives also thanks to our suppliers, from the long relationship built together, national and international suppliers, near and far, that can solve (quasi) all the needs related to the development of a motorcycle, by the supply of small spacers from 5mm up to the realization of an injection mold or the design of an ad hoc engine.

The company

In our company, This Milan in an industrial district, but at the same time in the heart of the city, we have a workshop for light machining such as turning, milling, sandblasting, welding and one dedicated to the coating space. In addition to this type of traditional processes, we can create components using a technology that for us represents the future of Given: 3D printing. The two machines we have in the company allow us to see done in less than 24 hours the parts that are modeled in 3D.

3D printing allows us then to get useful parts to dimensional checks during pre-production but also in some cases to have finished products.

Here from Given's all it takes to entertain us and make the customer happy.